Solutions for ‘Problem Glass’ in Buildings Before, During and After Installation

2017-01-30

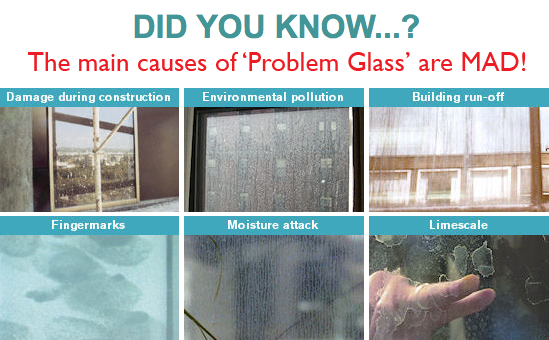

Moisture, Alkalinity and Dirt (MAD) can easily cause glass, exterior or interior, to become ‘Problem Glass’. Glass is all around us and, when new, it promises visibility, clarity and cleanliness. Unless glass is protected against MAD, it can easily break these promises before, during or after installation – with serious consequences for specifiers, fabricators, contractors, installers, building owners and occupants.

For more than 35 years, Ritec has developed and supplied innovative and cost-effective solutions for ‘Problem Glass’. These solutions provide either ‘prevention’ for new installations or ‘cure’ for glass already installed – reducing or eliminating the risks of call-backs, delays in construction and complaints.

‘Problem Glass’ is any glass that has broken, or is likely to break, its original promises of visibility, clarity and cleanliness. This causes glass to become increasingly difficult to clean and keep clean – a high-maintenance material of construction. In spite of frequent and intensive cleaning, Problem Glass can easily lose its original visibility and “sparkling” appearance.

‘Problem Glass’ can also fail to achieve industry standards for light transmission that were met at the time of installation. This has negative effects on daylighting in a building as well as reducing the well-being and productivity of its occupants.

‘Problem Glass’ is likely to be found anywhere one or more of the aggressive trio of MAD is present. The two biggest enemies of glass are moisture and alkalinity. Either individually or together, they can etch or dissolve the surface of glass, making it appear dull and sometimes white in appearance. Some dirt can damage the surface, and further harm can be caused in efforts to remove it.

Moisture can be in its liquid form, such as rainfall, or as a vapour in high humidity areas. Alkalinity comes from hard tap water, sea water and construction materials such as cement dust and building run-off from concrete, bricks or mortar.

Organic dirt does not normally attack glass but can attach firmly to the surface and be difficult to remove. For exterior glass, this includes traffic film, bird droppings and tree sap. For interior glass, organic dirt includes fingermarks and cooking oil vapours.

Inorganic dirt bonds chemically to glass and is difficult, if not impossible, to remove using conventional cleaning methods. Inorganic dirt on exterior glass includes sea spray, industrial emissions, metal oxides from railways and construction materials such as cement dust and building run-off. For interior glass, an example is limescale from hard tap water.

‘Problem Glass’ is most likely to be found in locations such as:

- construction sites

- sloped glazing – conservatory roofs, rooflights

- buildings with difficult access for routine washing

- glazing exposed to run-off from concrete, bricks, mortar, stonework, lead flashing, silicone sealants

- glazing in polluted areas – city centres, industrial estates, near railways, coastal

- interior glass – shower enclosures, sand-blasted glass, kitchen splashbacks.

If you need a solution to ‘Problem Glass’, contact us at info@csgt.me or call us at 03 353 555.

< Back to NEWS

2018-01-08

Introducing the ClearShield Eco-System in Lebanon

THE NEXT GENERATION OF RITEC CLEAR-SHIELD® FOR ...read more

2017-01-30

Solutions for ‘Problem Glass’ in Buildings Before, During and After Installation

Moisture, Alkalinity and Dirt (MAD) can easily cause glass, exterior or interior, to become ‘Problem Glass’. Glass is all around us and, when new, it promises visibility, clarity and cleanliness. Unless glass ...read more