The award-winning ClearShield System has been specially developed for the renovation, protection and maintenance of both new and already installed glass.

Just as metal rusts, glass is subjected to a corrosion process caused by reactions between the glass surface and atmospheric pollution. Even a single droplet of moisture on unprotected glass can produce sufficient damage to be visible in good lighting.

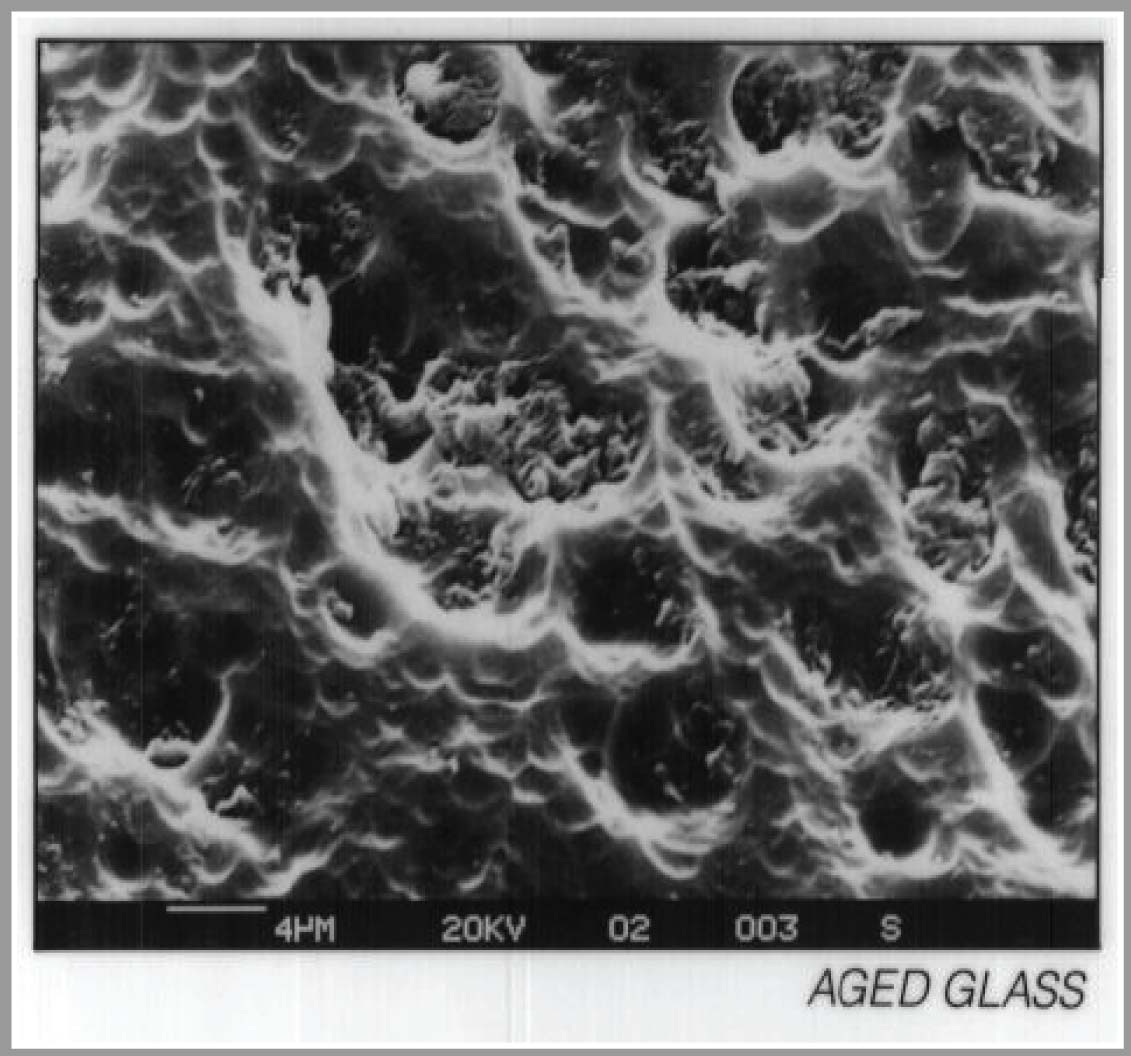

The surface of glass is not smooth and consists of microscopic peaks and valleys. Both organic and inorganic contaminants fill these, chemically reacting with the glass and firmly bonding to the surface. Because of this, cleaning glass becomes more difficult and visibility and appearance deteriorates.

The surface of glass after weathering

ClearShield: The Ideal Solution

ClearShield is a polymeric resin that uniquely cross-links with the glass and itself to form a strong chemical bond when applied to ordinary glass. It is completely transparent, chemically inert, non-hazardous and UV stable. Unlike a coating, ClearShield becomes part of the glass and will never discolour, peel or crack.

The result is ClearShield Low-M® (Low-Maintenance) Glass that prevents contaminants from bonding to the surface and resists damage caused by corrosion and chemical attack .

Unprotected glass is highly reactive with limescale, metal oxides, traffic Pollution

and silicone run-off

The surface of ClearShield Low-M® Glass is more resistant to corrosion, and it is 'non-stick' because it is chemically inert. This means that:

- less dirt and other contaminants stick to its surface

- when they do deposit onto its surface, they no longer chemically react with it, and are easier to remove

- the absence of dirt and other contaminants prevents staining and discolouration

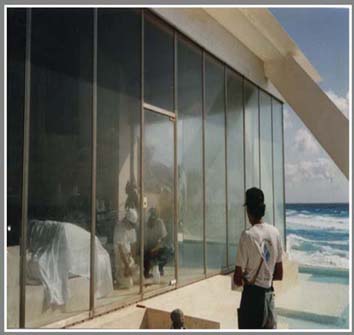

ClearShield’s versatility means it can be applied onsite for glass already installed or in the factory on new glass. Glass protected with ClearShield in the factory can save time and money during the construction of a building. Splatter from concrete, plaster and mortar, for example, can all be removed from ClearShield Glass, so costly glass replacement and lengthy delays as a result are avoided.

For the end-user, ClearShield is:

• always easier to clean and keep clean

• stays cleaner for longer

• resists staining and discolouration

For glass manufacturers, processors and fabricators that supply glass protected with ClearShield to its customers, our company offer a comprehensive package:

• Added value system to help increase sales and profits

• A technology that has proven its claims with more than 27 years experience worldwide

• A system that offers personalised solutions to all glass users

• Safe and non-hazardous products

• Versatile methods of application that can adapt to all volumes of production

• Unique renovation solutions for already installed glass

• Local supply, training and subsequent sales, marketing and technical support.

Casa Caribe, Mexico

Normal glass while raining ClearShield glass while raining

Hydrocarbon contamination Silicone contamination

2018-01-08

Introducing the ClearShield Eco-System in Lebanon

THE NEXT GENERATION OF RITEC CLEAR-SHIELD® FOR ...read more

2017-01-30

Solutions for ‘Problem Glass’ in Buildings Before, During and After Installation

Moisture, Alkalinity and Dirt (MAD) can easily cause glass, exterior or interior, to become ‘Problem Glass’. Glass is all around us and, when new, it promises visibility, clarity and cleanliness. Unless glass ...read more